Smart Asset Solution in Complex Manufacturing Setting

Life science companies and medical device manufacturers can maximize operational efficiencies when critical product data and information is readily available throughout their value chain — from manufacture to distribution to end use. Tego’s AIP solution benefits pharma, medical device manufacturers and healthcare service providers by providing unprecedented manufacturing visibility and availability of product and regulatory compliance data.

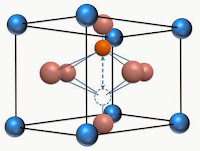

Tego Platform captures product data rugged enough to survive sterilization and other manufacturing processes, while enabling aseptic manufacturing. This breakthrough technology is bringing the benefits of the Industrial Internet of Things (IIoT) to new industries such as life sciences and healthcare. As demonstrated in the solution brochure, the benefits come in many forms, including dramatic increases in process efficiencies and reduced production costs.

What exactly is the 10/90 rule as it applies to the Internet of Things (IoT)? According to Dr. Mazlan Abbas at the

What exactly is the 10/90 rule as it applies to the Internet of Things (IoT)? According to Dr. Mazlan Abbas at the